Servo press advantages compare with traditional press:

◆ Speed can be set and changed freely during machining with incomparable production usability.

◆ Compare with traditional press, servo press with less mechanical parts, which is easier for maintenance; speeding up of return stroke to significantly increase production efficiency.

◆ Stoke height and performance can be programmed with production flexibility.

◆ Optimized performance to improve part quality and prolong dies service life.

◆ Efficient drive solution to decrease energy consumption.

◆ Fine turning with hand wheel to greatly shorten die test time. HMI interface:

◆ Moving curve programme (crankshaft mode, multi-link mode, pressure maintaining mode, single side mode, tick-tock mode, muting punching mode, repeat pressurizing mode, free programming mode).

◆ Production state inspection, preset and counting, etc.

◆ Real time indicating of motor torque, crankshaft angle and slide displacement, etc.

◆ Dies data management system.

Slide performance mode:

◆ General crankshaft performance mode.

◆ Link performance mode.

◆ Repeat pressurizing of short stroke and low speed blanking near BDC to reduce noise, pressure maintaining and pressure.

◆ Easy to achieve control with feeding device.

◆ Proper operating mode is selected by trial operating and programmed freely by customers.

◆ Control function of instant energy releasing during machining.

PRODUCT:

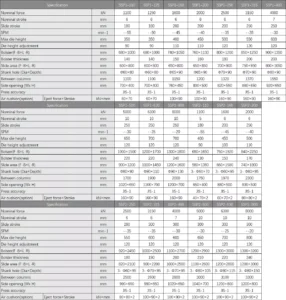

SSP Series Gantry Type Servo Press

Product Related

SP1 Series Gantry Type Single Point Press With High Accuracy High Performance

JH25 Series Open Front Two Point Press With High Performance

CP2 Series Open Front Two Point Press With High Accuracy High Performance