CNC Hydraulic Swing Shearing Machine for Precise Metal Cutting

Product Advantages

High Precision:

Energy Efficient:

Durable Construction:

User-Friendly:

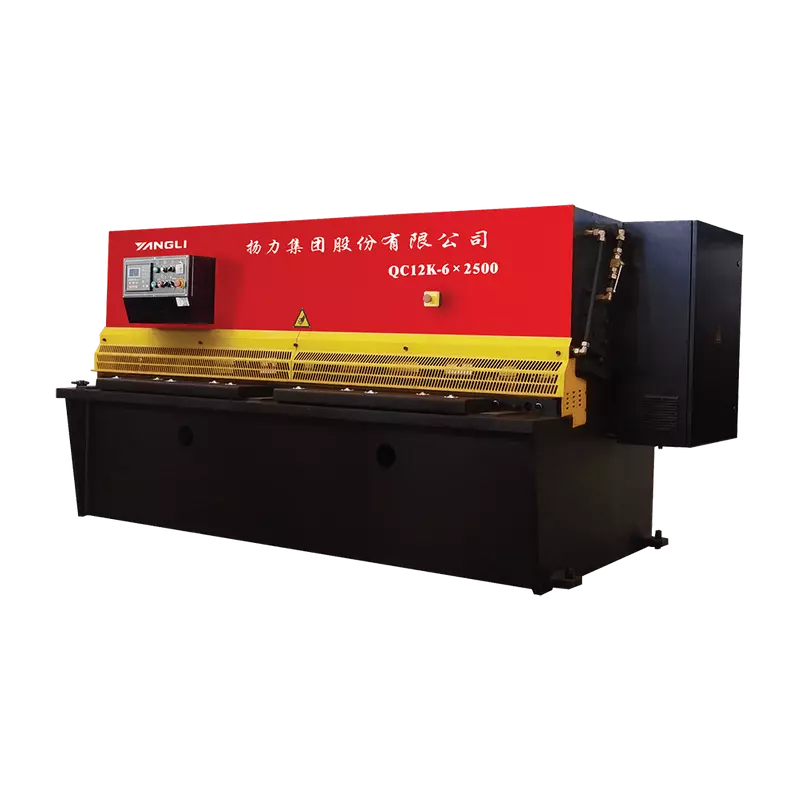

CNC Hydraulic swing shearing machine

Product Displays

Why Choose Our CNC Hydraulic swing shearing machine ?

Precision Engineering

Precision Engineering

Precision Engineering

Precision Engineering

Precision Engineering

Frequently Asked Questions (FAQs)

What materials can the CNC Hydraulic Swing Shearing Machine cut?

The machine is capable of cutting a wide range of materials, including mild steel, stainless steel, aluminum, and copper. This versatility makes it suitable for industries such as metal fabrication, automotive, aerospace, and construction, handling both thin and thicker materials efficiently.

How precise is the cutting process?

A: The cutting process of the CNC Hydraulic Swing Shearing Machine is highly precise due to its advanced CNC control system. This system ensures that each cut is accurate and consistent, even for complex or high-precision parts. The combination of hydraulic drive and CNC control minimizes errors and improves the overall efficiency of the cutting process, ensuring reduced material waste and better quality parts.

Is the machine suitable for large-scale production?

A: Yes, the CNC Hydraulic Swing Shearing Machine is designed for high throughput and can handle large-scale production demands with ease. The robust hydraulic system and efficient CNC controls allow for fast, continuous operation without compromising on cutting quality. This makes it perfect for industrial-scale applications, where large volumes of material need to be processed quickly and efficiently.

Can the cutting angle be adjusted?

A: Yes, the cutting angle is easily adjustable on the CNC Hydraulic Swing Shearing Machine. The adjustable cutting angle feature is essential for accommodating different material thicknesses and achieving various cutting results. This flexibility allows for precision cutting across different materials and thicknesses, making it suitable for a wide variety of applications, from thin sheets to thicker plates.

What maintenance is required?

A: Regular maintenance includes cleaning to remove debris, lubrication of moving parts, periodic inspections of key components (blades, hydraulics, etc.), and calibration of the CNC system to maintain cutting accuracy and machine efficiency.

Is training available for the machine?

A: Yes, comprehensive training is available for both operation and maintenance of the CNC Hydraulic Swing Shearing Machine. This training ensures that operators understand how to use the machine safely and efficiently. It also covers basic troubleshooting, maintenance practices, and how to program the machine for various cutting tasks. Proper training helps maximize the machine’s potential and minimizes the risk of operational errors.

What warranty does the machine come with?

A: The machine comes with a one-year warranty, covering defects in materials or workmanship, ensuring peace of mind for the buyer.It ensures that the machine remains in optimal working condition, and any issues related to materials or workmanship are resolved promptly.