Welcome to Yangli Press

MACHINE PRESS EXPERTS,

LEADING SMART MANUFACTURING

We manufacture high-performance industrial presses designed to increase the precision, speed, and reliability of manufacturing processes. Our solutions integrate advanced automation and control technologies to optimize production, reduce operating costs, and improve quality at every stage of metal forming.

METAL FORMING AND SHEET

METAL MACHINE

Products cover punching, forging, laser, sheet metal processing, hydraulic and automation, etc. Yangli focuses on providing solutions of variable middle an premium sheet metal machining and intelligent production lines,mation, etc.

0

Yangli Group was founded in

0

Covering an area of more than (acres)

0

Existing employees of more than

YANGLI GROUP

EXPERT OF METAL FORMING-

PRESSING THE FUTURE

A industry leading middle and premium metal forming press expert-YANGLI, was established in 1966 and located in the historical and cultural city named Yangzhou, covered an area of more than 1066720m², with more than 4000 employers and now total assets of RBM 2.8 billion.

Learn MoreYangli has five subsidiary corporations, which are Yangli Machine Tools Co.,Ltd.,Yangli Heavy Duty Machine Tools Co., Ltd., Yangli Precision Machine Tools Co., Ltd.,Yangli CNC Machine Tools Co., Ltd. and Yangli Hydraulic Machine Tools Co.,Ltd. Yangli established a Yangli Group Research Institute with 7seven research divisions with more than 350 engineering technicians

Metal forming equipment prepare Leaders outstanding qualities since 1966

Producion Scale

The group currently has three major production bases: technology entrepreneurship park, technology industry park, and technology industry park. Covering an area of 1670 acres, it has a modern standard factory building of 600000 square meters, 6 complete machine production lines, and an annual production capacity of 30000 sets of complete machines.

Production specialization

The group has five major production divisions: Yangli Machine Tool, Yangli Heavy Machinery, Yangli Precision Machinery, Yangli CNC, and Yangli Hydraulic.

Production Lines

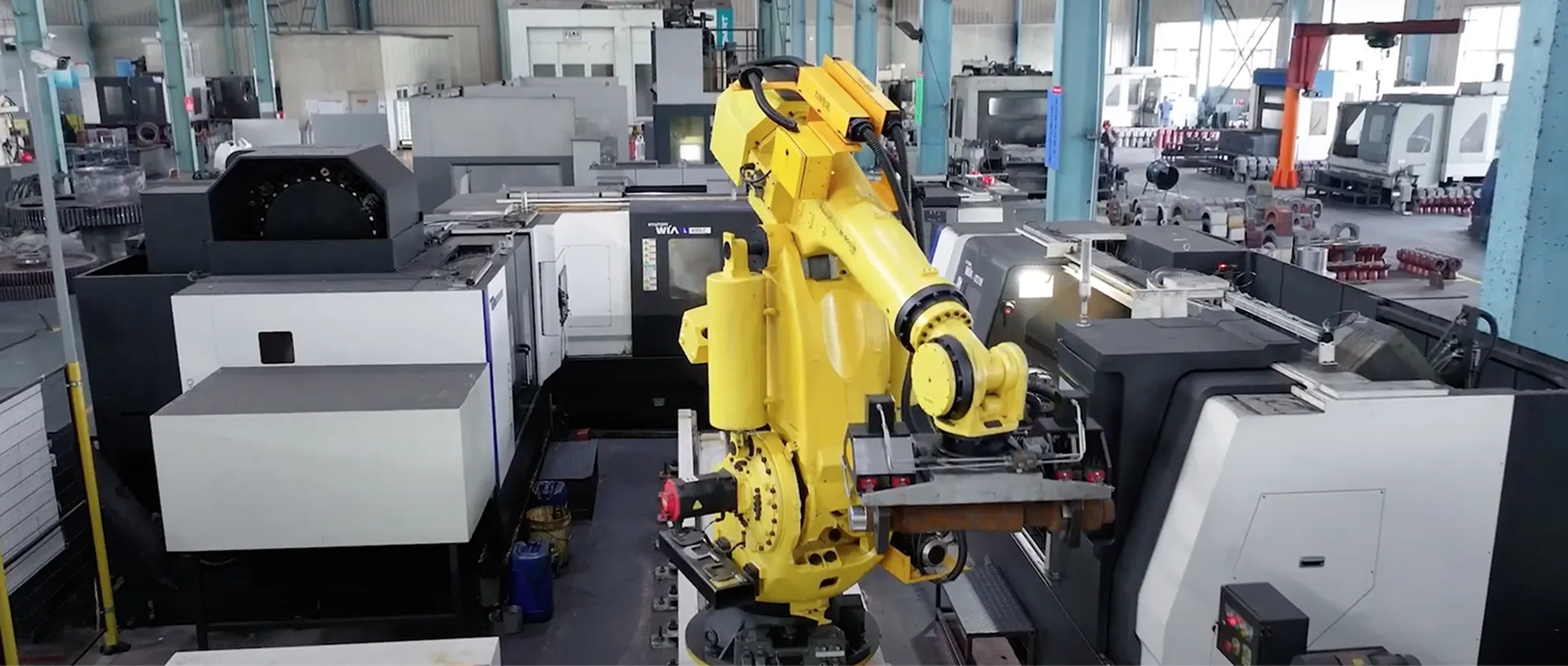

High end equipment

The group has a strong advantage in specialized parts production, with one copper casting and processing workshop, two blank casting workshops, two lost foam production lines, five welding workshops, robot welding for small machines, and eight parts processing workshops. Key parts such as crankshafts, clubs, air cushions, balance cylinders, clutches, and connecting rods have all been professionally produced.

Agile Manufacturing Integrated Control Platform (AMCP)

In response to the changing market and small batch customized production needs, the group has created a personalized "Agile Manufacturing Integrated Control Platform" to track, identify, analyze, and control each node of the business lifecycle chain, providing data support for decision-making, business objectives for management, and control objectives for execution.

Manufacturing Collaborative Management Platform (MES)

To enhance the granularity of manufacturing control, the group has introduced a production process execution system for manufacturing enterprises, which integrates and decomposes production information and manufacturing data at the workshop execution level into various management modules, creating a solid, reliable, comprehensive, and feasible process management platform for the enterprise.

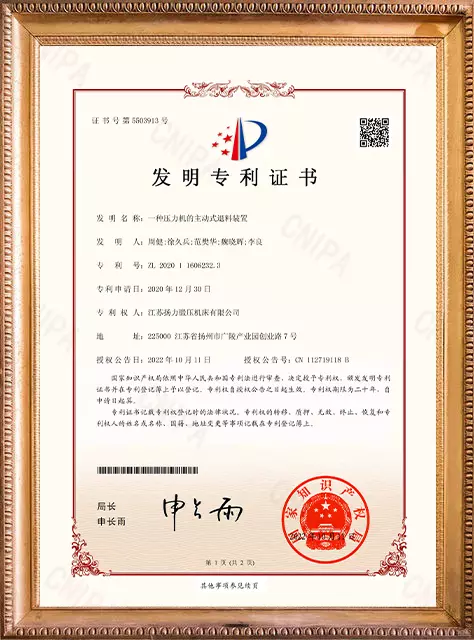

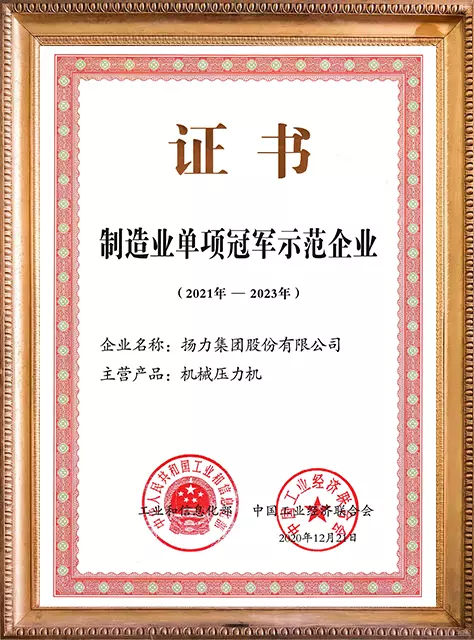

Certificates For Stamping

Press Machine

YANGLI Group has obtained 727 authorized patents, including multiple national and provincial scientific and technological awards, and is a demonstration enterprise for manufacturing champions, fully demonstrating the company's outstanding strength in technological innovation and industry standard setting.

SOLUTIONS

Non-metallic formation

Processes non-metallic materials by stretching, bending, compressing, and cutting. Advantages: Lightweight, economical, environmentally friendly, and easy to work with. Used in automobiles, electronics, and aerospace, especially in fiberglass-reinforced doors.

Apliance Industry

Function: Automation with hydraulic presses and mechanical arms. Features: Efficiency, low cost, and automated management. Application: Washing machine casings and appliance parts.

Metal packaging industry

Function: High-speed presses for precision metal forming. Features: High efficiency, quality, and processability. Application: Production of cans and drums for food, beverages, and medicine.

Automotive industry

Function: Process automation with closed presses and loading equipment. Features: High efficiency, quality, and automated control. Application: Production of automotive chassis and shells.

New energy vehicle power battery

Function: Automation with stretch presses and automatic loading equipment. Features: High efficiency, quality, and precision. Application: Aluminum battery shells, square and circular.

Home Appliance

Function: Metal processing with laser cutting, bending, and stamping. Features: High efficiency, precision, stability, and intelligence. Application: Car body shells and precision electronic components.

Forged industry

Function: Metal processing with laser cutting, bending, and stamping. Features: High efficiency, precision, stability, and intelligence. Application: Car body shells and precision electronic components.

TEAM

The excellent technological expertise of our employees

MANUFACTURE

The excellent world top level machining equipment

ONE-STOP

One-stop solutions for all metal-forming and sheet metal industrial

SERVICE

All round and minute services around the world

Contact Us Soon

Our service standard is: be focused, professional, and efficient! Our business philosophy is: the customer comes first, service creates value!